Dongteng Machinery has a number of 10 professional development team engaged in mold industry for decades, with the industry leading CAE experience and technology, to help customers optimize the product structure, develop the best molding scheme and the most economical production mode for the purpose. Leading CAM technology and standardized and informationized CAM management process are the guarantee of customers' high quality and high efficiency requirements.

CAD/CAE/CAM

Our company uses CAD software, 2D to AutoCAD, 3D CAD mainly uses ProE, in the CAD design process, developed in line with the company's standard module, thus shortening the mold design cycle, improve the design efficiency.

CAM software adopts CIM: programming software, interface and CAD interface are interlinked to form a perfect combination of CAD and CAM, the use of parameterization in the process of programming, making programming more reasonable, more efficient, more perfect processing.

CAE simulation software is ready to purchase Maga software from Germany, which is the most advanced software in the world for simulation and prevention of die-casting defects in the process of product production. This software can better optimize mold design and process parameter formulation.

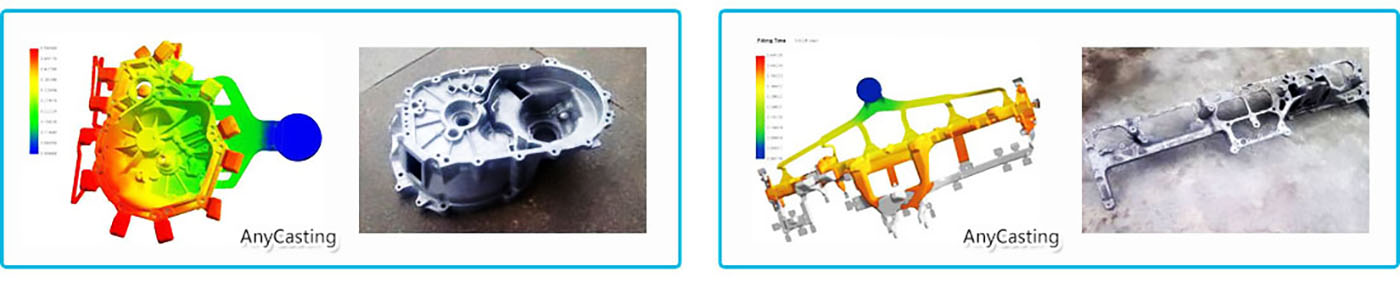

Modal flow analysis diagram